Your Measurement at the MRI Flow Lab

The research team at the MRI Flow Lab has extensive experience in planning, designing and conducting MRV experiments. We will happily provide you with all our expertise in planning and implementing your measurement campaign. Please keep a few key facts of MRV in mind:

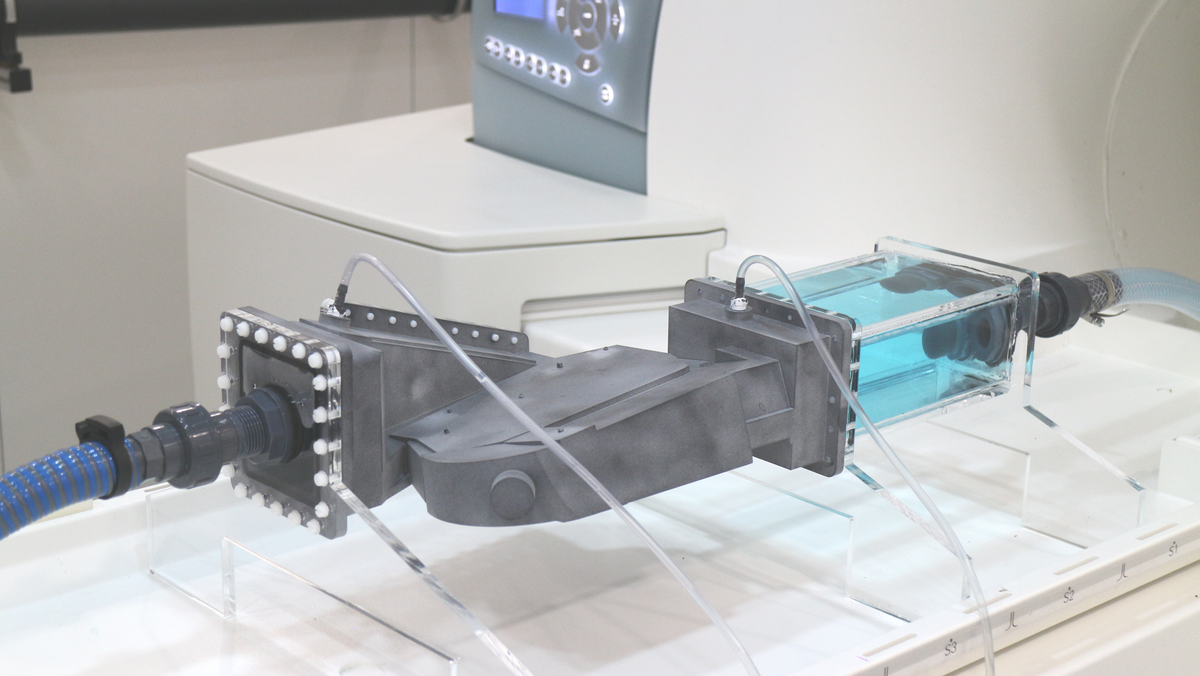

- No metal parts inside the region of interest. Exceptions are possible, but the fewer the better.

- 380 mm maximum available measurement diameter inside the MRI system.

- Spatial resolution commonly about 1 mm, up to 0.3 mm is feasible.

- Temporal resolution of MRV only allows for quantification of (phase-averaged) mean parameters.

- Best practice materials for flow models: polyamid (PA), acrylic glass (PMMA) and polyoxymethylene (POM).

- Optical access, tracer particles or refractive index matching are not required.

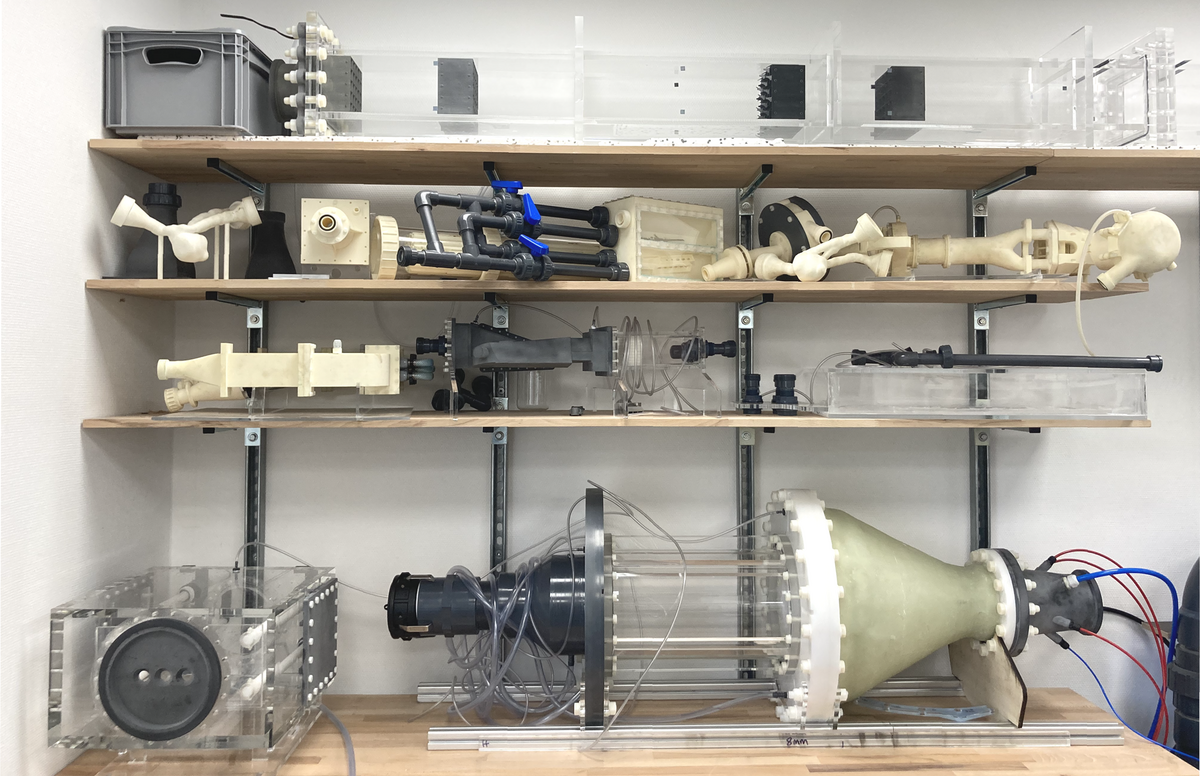

Our MRI system is specified for measurements in fluids with a high amount of hydrogen such as water or oil. Gas flows at low Mach-number, such as in turbine blade cooling systems, can be modeled by a water flow for the MRV measurements by applying similarity laws. Millions of data points of the mean velocity field can be captured within just a few hours at a spatial resolution up to 0.3 mm. In combination with Rapid Prototyping or Additive Manufacturing methods, MRV enables new possibilities for the design and study of flow components. Where previously only numerical methods were available, MRV can be used to generate experimental data comparatively quickly and cost-effectively. After a careful planning phase, the models to be measured are manufactured using various manufacturing processes. For complex structures, additive manufacturing for polyamide is mostly used. Channels, pipes and visual inspection windows inside the measurement region are commonly manufactured with acrylic glass. The magnetic susceptibilities of these materials are close the one of water which is beneficial for the measurements.

If you are interested in collaborating with the MRI Flow Lab for your measurements, please get in touch with one of our team members.

Funding Opportunities

OFFERR

The MRI Flow Lab is listed in the European User Facility Network Catalogue (OFFERR). Researchers and developers in the field of sustainable nuclear engineering can apply for exclusive OFFERR funding to use the infrastructure of the MRI Flow Lab for their research without any further costs. Two options are available: fast-track for up to six months and 50k € or complex projects for up to 18 months and 1M €. The funding is open for proposals that address the strategic research and innovative agenda (SRIA) of the Sustainable Nuclear Energy Technology Platform (SNETP). For further information on OFFERR and funding, please visit https://snetp.eu/offerr/.

FAQ

Our flow models are commonly manucatured using plastic materials such as acrylic glass and polyamid. With the latter, 3D prints of complex components can be created quickly and cost-effectively. This study analysed which materials are most suitable: Wapler et al. 2014, doi: 10.1016/j.jmr.2014.02.005.

Metal parts inside the region of interest should be avoided, but under certain circumstances, materials such as copper can be used. In a recent study, we performed temperature measurements in a pin fin array with copper pipes: Bruschewski et al. 2021, doi: 10.1016/j.mri.2020.10.006

The common spatial resolution is about 1 mm in all three spatial direction. Measurements up to 0.3 mm resoltuion are possible. In a 2D measurement, the slice thickness can go down to 3 mm and up to 100 mm for spatial averaging. An analysis of different spatial resolutions on the measurement of porous media was published in Bruschewski et al. 2021, doi: 10.3390/physics3040079

An MRV measurement takes a few minutes for 2D measurements and up to several hours for 3D measurements. MRV can thus only provide the mean parameters of the flow field. For periodic flows phase-averaged measurements are possible, based on a measurement method proposed in this study: Markl et al. 2012, doi: 10.1002/jmri.23632

With MRV a cuboid volume is measured including the fluid volume but also wall materials and sourroundings. The spatial resolution is constant within a spatial direction. The boundary layers of the flow can be measured within the descretization limitis of the measurement.