MRI Laboratory for Engineering Applications

MRV – Key Capabilities

MRI Flow Lab

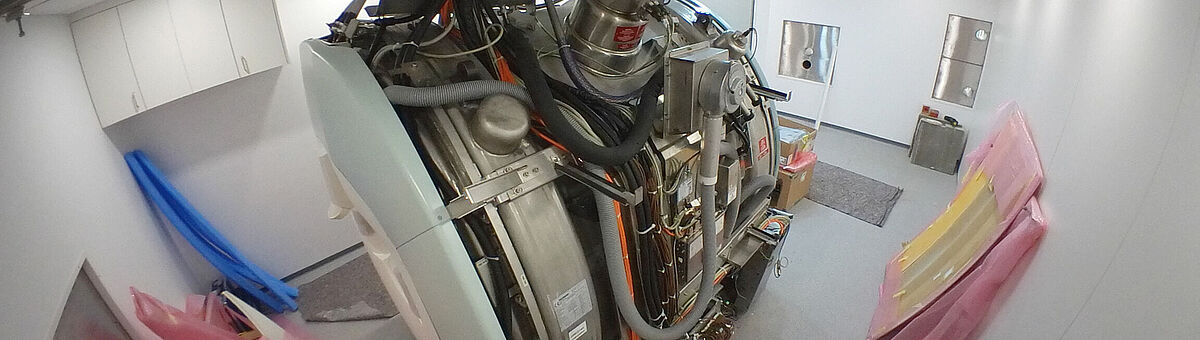

The unique layout of the laboratory enables high-precision experiments with very short set-up times. Particular attention was paid to the flexibility and upgradability of the laboratory for future research tasks as well as stable measurement conditions and operational safety. The unique features of the laboratory include:

- Freely configurable flow circuits with high-performance pumps and large-volume tanks

- Complete electromagnetic shielding of the MRI room with six freely configurable filter plates for pipe feedthroughs

- Sealed floor with drainage for safe working with liquids

- Ceiling rail system above the MRI and wall mounting systems for fast and safe experimental installations

Another special feature of the MRI flow lab is the overall arrangement of the rooms. The axis of the MRI system is aligned with two filter panels in the walls of the examination room as well as with the windows in the building walls. With this alignment, it is possible to place an extremely long experimental setup throughout the building in the MRI. Thus, in extreme cases, a nearly 100m-long channel can be examined inside the MRI.

MRI Scanner - Technical Data

MAGNETOM Trio Siemens

- 3 Tesla full body MRI Scanner with 600 mm bore diameter

- highest magnetic field homogeneity in this scanner class

- 40 mT/m or and 200 T/m/s magnetic field gradients

- variety of transmitting and receiving coils with up to 32 channels

Other Equipment

Controlling and Capturing of Boundary Conditions:

- Various types of mass flow meter (ultrasonic, magnetic-inductive, and coriolis) and temperature probes

- Heating and cooling systems for constant fluid temperature

- Fiber-optical temperature measurement system for reference measurements inside the region of interest

- Analog and digital differential pressure sensors

- Surface roughness measurements

Technical Equipment

- Reverse osmosis system for concentration measurements

- Compressed air supply up to 8 bar

- Laser sintering system

- Fully equipped workshop with 3D printers, laser cutter and other equipment to manufacture experimental setups

Complementary Measurement Methods

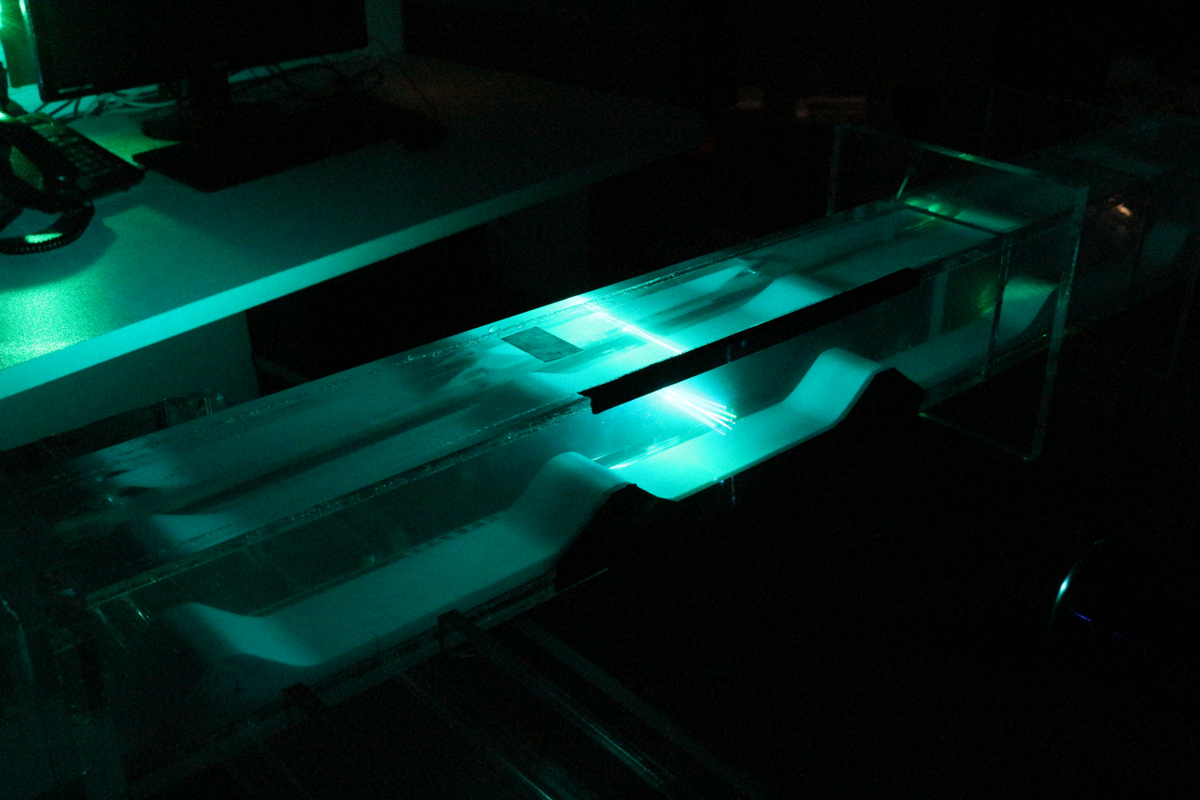

MRV enables a comparatetively quick and cost-efficient 3D insight to complex flows, enabling analysis of many different flow configurations in a short time. For some applications, however, it may be useful to complement MRV measurements with other measurement techniques. At the Institute of Fluid Mechanics we can offer the following measurement methods:

- Particle Image Velocimetry (PIV, TR-PIV, µPIV)

- Planar Laser-Induced Fluorescence (PLIF)

- Laser Doppler Velocimetry (LDV)